Our watches are assembled in Scotland from parts made in the UK and around the world. We’ve chosen to highlight our production partners here as we believe transparency is an essential step towards achieving better ethical and environmental standards.

Since Paulin was launched in 2013, we have been steadily developing our production habits from traditional, large-scale production to a leaner, more local model. We also work directly with component manufacturers rather than with an assembly partner, which helps us produce a better value product, and provides more control over the finished result.

Central to our methodology is the provision of a repair service for our products, done in-house by our watchmakers. A product that is built to last and well maintained is a product that is better for both the consumer and the environment.

Dial

We are one of the very few companies worldwide using anodised aluminium for watch dials. Our Neo dials are milled from a solid sheet of aluminium, anodised and dyed in the UK. The rejection rate of this process can be as high as 30% and is seen by many as too problematic. After years of development, we have reduced this to less than 5% by stripping and retreating dials that don’t initially pass the test. Read more about the anodising process here.

Our Modul dials are produced in Germany by renowned dial maker, Cador. They begin as a machined brass blank before details are added, and the surface is painted with opaque lacquer. Numerals and markers are then pad printed onto the face, using multiple layers to build up a relief.

MANUFACTURERS

anOrdain, Glasgow, UK

Private individual, Warwickshire, UK

Cador, Eimeldingen, Germany

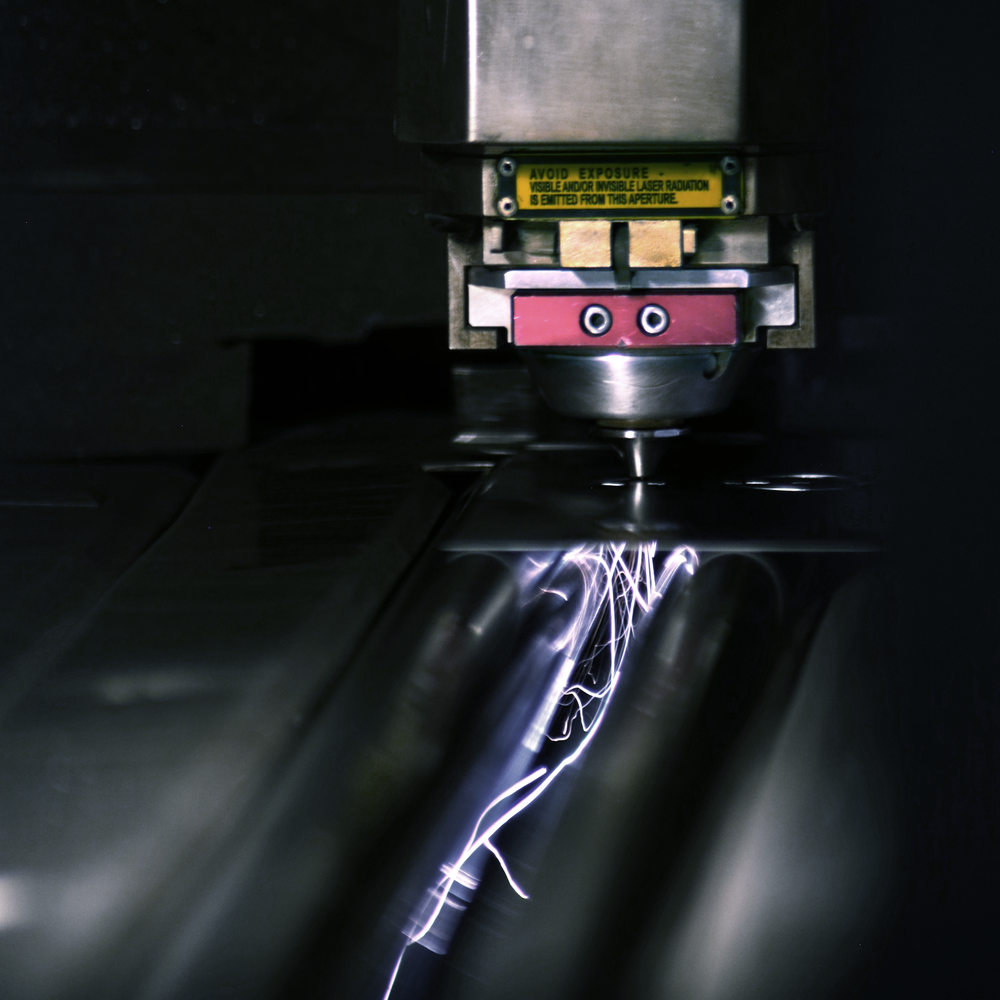

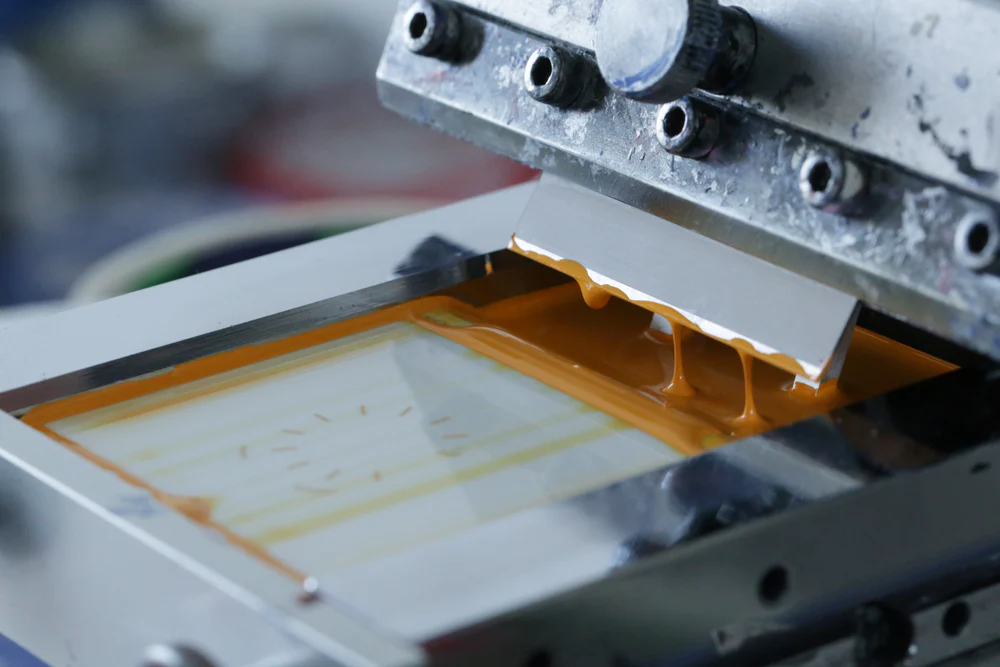

printing the Neo dial

printing the Neo dial

Case

Our watch cases are made using 316L Stainless Steel, a surgical grade that is highly resistant to corrosion. Our manufacturer, Chung Nam Watch, was founded in 1935 and produces high-quality work for many high-end watches. With their incredible attention to detail and willingness to try new things, Chung Nam Watch is one of our favourite partners to work with.

CRYSTAL

For both the Modul and Neo, we use box-section hesalite crystal because it leaves enough space for the hands and the 5.3mm movement while reducing the thickness of the case. This adds to their distinctive, vintage aesthetic and creates a watch that feels slimmer. The use of hesalite also allows scratches to be polished out easily.

MANUFACTURER

Chung Nam Watch, China

Hands

Our hands are designed in-house and manufactured in India by KDDL, the largest supplier of hands to the Swiss watch industry.

Watch hands materiality varies based on usage. Aluminium hands are cheap to produce and often found in accessible watches. Mid-to higher-end hands use brass (or steel for those thermally blued). The Neoand Modulwatch hands are stamped from sheets of brass and then either painted with lacquer or chemically plated.

MANUFACTURER

KDDL, India

Movement

We source watch movements from well-established manufacturers in Japan and Switzerland, choosing tried-and-tested products that will provide you with years of service.

The Paulin Neo uses the Seiko NH35A automatic, an affordable workhorse that performs with competitive accuracy. It’s widely used, making replacement or serving easy and affordable. Produced in both Japan and Malaysia, we choose to use the Japanese variant, as we’ve found the Malaysian version can be over-oiled in the factory, with this oil picking up grime and clogging the movement.

The Modul Quartz uses the classic Swiss ETA 955.112. Although no longer in production, we’ve managed to source a small batch of new ‘old-stock’. It’s incredibly reliable and accurate, with a range within +/- 10 seconds per year under normal conditions, and its battery can last up to 7 years.

The Modul Mechanical uses the D100, a modern production of the ETA 7001, by renowned movement maker, La Joux-Perret. The design has been in production since 1971. It’s one of the slimmest on the market at only 2.5mm, and LJP’s version has 50 hours of power reserve. Paulin is, as far as we know, the first watchmaker in the world to use the D100. Our units feature the highest level of finishing and adjustment, ‘Top Grade’.

MANUFACTURERS

Seiko, Japan

ETA, Switzerland

La Joux-Perret, Switzerland

Strap

At Paulin, we take pride in our watch straps. We work with Fluco, a seventy-year-old family business, and one of just two remaining strap makers in Germany. Strap-making requires 52 machines and is a time-consuming process.

We also source specialist leathers directly from tanneries, such as our British Bridle leather from Spire Tannery in England.

We work with San He Xing in China and Staib in Germany to produce our two Milanese mesh bracelets.

Read more about our straps here.

MANUFACTURERS

Spire Tannery, England

Tempesti Tannery, Tuscany

Fluco, Germany

Greenland Watch Limited, Hong Kong

San He Xing, China

Staib, Pforzheim, Germany

Packaging

Paulin’s packaging has been plastic-free since 2015. We use eco-friendly kraft paper, card and cork, all of which are 100% natural and recyclable. We also source our packaging from the UK wherever possible to reduce shipping. Our custom-made cork inserts are made in Portugal from pulped off-cuts, in a process that uses electricity powered by the cork itself.

We aim to streamline our packaging as much as possible, so your watch or clock will arrive safely, but with minimal waste.

MANUFACTURERS

3D Cork, Portugal

Fedrigoni, Italy

GF Smith, England

Progress Packaging, UK